| |

|  |

Formco Plastics Equipment & Capabilities

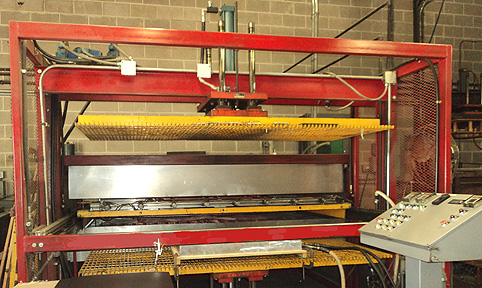

This forming machine has been in use since 1958. Used primarily for prototypes that require a deep draw, we have maintained this machine as an option for our customers to obtain large sample parts without costly set up charges. |

Our 5-axis, CNC routers provide high-speed multi-dimensional cutting and finishing for even your most complex parts. We have finishing techniques today that were impractical to consider just a few years ago. This capability is the result of our advanced technology and equipment, plus 35 years of hands-on experience and expertise.  Proprietary designed, hydraulic, single station pressure former. Capacity: 48"x96x18. This hydraulic single station pressure former was designed and built by Formco to handle the demand for extremely high detail pressure formed parts. Because of Formco's design and engineering of this machine, it can produce parts that rival injection molding. Thermoplastic Materials Formco Plastics sources the highest quality materials from our extensive network of leading plastics suppliers. A selection of the most commonly used custom thermoforming materials are listed below.

|

Home | About Us | Contact Us | Thermoforming Services | Equipment/Capabilities | Award Winning Designs Vacuum Forming | Thermoforming Products | 5 Axis CNC Routing | Plastic Fabrication | Drape Forming | Heat Bending | Die Cutting | Assembly Acrylic Forming Chicago Chicago Distortion Forming Chicago Vacuum Forming Thermoforming Bensenville Thermoforming Chicago Thermoforming Elk Grove Village Vacuum Forming Elk Grove Village Proudly Manufactured All Rights Reserved © 2015 / Formco Plastics, Inc. / 630-860-7998 / Fax 630-860-9181 904 Fairway Drive - Bensenville, IL 60106 Web Site Development: ProPlanet Internet Solutions, Inc. |